How are shoes Made?

Construction Methods Used in Shoe Manufacturing

You could easily be forgiven for taking no interest in how your shoes are made. The truth is the method of construction of a shoe has a significant bearing on comfort, suitability and durability. Therefore it is worth taking into consideration when you are picking a pair of shoes to buy.

The entire shoe manufacturing process is worthy of a large amount of detail. It is a remarkable industry in the level of detail involved in making high quality shoes. For the purpose of this blog we are going to focus on the “making department” which is a small but critical part of the process. This is the stage where the upper is attached to the sole of the shoe and it has a massive bearing on how shoes perform.

The choice of construction that a manufacturer decides to use depends on three factors. These are the purpose of the footwear, the price of their shoes and the machinery and materials that they have available.

THE MAKING DEPARTMENT

Based on our ranges of shoes, there are generally three common means of attaching the upper to the sole unit:

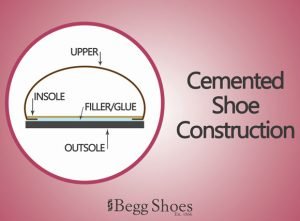

CEMENTED

A great example of a cemented shoe brand is Gabor that use the Hovercraft technology in their sole. Though these styles have different uppers they are actually all made using the same sole unit. The leather uppers are pulled over a last and simply attached to the rubber sole unit with glue.

What are the pro’s of cemented shoes?

The cemented construction is widely acknowledged as one of the simplest, quickest and more cost effective means of making shoes. This means that for you, our customers, the shoes will cost less. That doesn’t necessarily mean they won’t be a great pair of shoes. This is because the majority of shoes sold in the UK are made using a cemented construction. Gabor use this method and are one of the best quality shoe manufacturers in the world.

INJECTION MOULDED POLYURETHANE (PU)

At Begg Shoes we are big fans of injection moulded PU as a construction method. Brands that specialise in this method of construction include Legero, Hotter, and ECCO.

ECCO are the best in the world at using this construction method to make shoes. A great example of the technology is their latest Gore-Tex Surround technology style. This style is probably the most technologically advanced shoe in the market due to the complexity of the construction methods involved.

At really high temperatures polyurethane melts into liquid form and can be injected using a high-tech machine. This clamps a metal mould around the upper of the shoe. The shape of the metal mould determines the shape and appearance of the sole unit. Nowadays, this technology from ECCO is so advanced that the styles of shoes that can be made are remarkable. Historically, it was accepted that shoes can only be made using PU injection moulding if they are flat but nowadays they can make shoes with a heel.

What are the pro’s of shoes made with Injection moulded PU?

Three key words are always soft, light and flexible! A high quality grade of PU will also be extremely hard wearing (the most hard-wearing you can buy & much better than a rubber sole). In our view, at least on a practical level, injection moulded PU shoes are a must have for anybody. They will provide long lasting comfort and last for much longer than a cheap pair of shoes. Another added benefit is the bond between the upper and the sole unit is rarely if ever broken. This means your shoes are highly unlikely to fall apart and the water penetration is reduced on a soaking wet Scottish day!

are there any cons of PU injection moulding?

Not a lot in our view, other than aesthetics. You cannot make beautiful high heels with injection moulding.

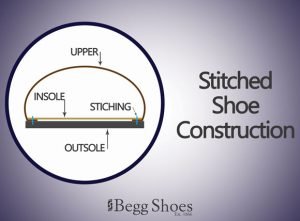

STITCHED

What we call a “stitch construction” has become a really popular style for comfort shoes. Here at Begg Shoes they are becoming a big hit with our customers. The method involves stitching the side wall of the sole unit to the upper using a specialist stitching machine (not just a sewing kit!). Examples of brands that use stitch construction to great effect are Rieker shoes and Remonte shoes.

What makes stitch construction shoes good?

Distinctive style and supreme comfort are the main reasons. They are often the most flexible shoes that money can buy. Stitch construction allows manufacturers to use polyurethane (eg. Rieker shoes are in fact PU – just not injection moulded). Polyurethane is always light and, with the suitable density and quality, is cushioned and shock absorbing. This is essentially why Rieker claim their shoes are “Antistress” and we discuss this in our blog about How Rieker Shoes Fit. The shoes are extremely comfortable owing often to their stitch construction, soft uppers and stitch construction. Another added benefit to stitch construction is that it is a cheaper method of construction. This means that the price is much lower for you, our customer.

What are the cons of stitch construction shoes?

Water penetration in-between stitch holes is the main drawback of stitch construction. Our advice to customers to overcome this downside is to apply a neutral shoe cream into the stitch holes nearest the sole unit. This area of the shoe is most exposed to potential water penetration and application of polish can massively reduce this. (This does not change product description to that of being waterproof!). Regular use of shoe polish or shoe cream will help to extend the ‘life’ and overall appearance of your shoes.

Shoe Lasts

Shoe lasts have a massive impact on how a shoe will fit. If a last is poorly designed then all shoes made on the same last will most likely not fit.

Before we go into detail, first lets explain what a last is…

What is a shoe last?

The last is usually a similar shape to the foot, but not identical. It is the shape on which the shoe is formed and must allow the foot to stand still. A good last will give the shoe a good fit in several different styles which can be seen below. Some lasts do not have a long shelf life if the design of the shape is quite fashionable. In this instance, the last would only have a life of two or three years. Other lasts have been the same for years and are much coveted in the shoe industry. A well designed last can be worth a lot of money!

At Begg Shoes we place great value on the last as it has a direct impact on comfort. We try to buy shoes that have been built using a well designed last. That way we know they should fit properly and be comfortable.

The design of the shoe, the purpose of the shoes and the method with which the shoe is manufactured will all affect the shape of the last. Different style of shoes made on the same last but using different materials will fit differently.

A last is a mechanical form that has a shape similar to that of a human foot. It is used by shoe manufacturers in the making of shoes. Lasts typically come in pairs and have been made from various materials, including wood, iron and plastics.

How is a shoe last made?

A last is designed for the shoe manufacturer and the original last was cut from a block of wood by hand. Now these are produced by a three dimensional CAD CAM system.

- Template designed and cardboards cut outs made.

- Material then cut to the required shape.

- Model made to check dimensions at specific places – once satisfactory production of whole size range made.

- Working last cut into two pieces & usually hinged together – so that it can be removed easily from the shoe without damaging it.

When a bespoke shoemaker creates a last for a customer and their feet, a new last won’t be made. Instead, extra pieces will simply be ‘tacked’ on to the existing last to cater for the ageing foot.

Importance of the Last

The original designer of the last has a difficult job as they need to create a last shape based on average feet and an average fitting and to suit any style. This aesthetically acceptable shape of a last must play its part in creating shoes to accommodate feet which can be far from aesthetically pleasing – at times a balance needs to be struck between how nice a shoe looks and how practical the shoe is. The best last designers can do both!!

The last model maker has to have a full knowledge of the anatomy and physiology of the foot and be aware of the changes for gender and age. A last which has been designed for a women 25-35 year old women with a 5C fitting will be different to that of a last designed for 70 year old women of the same size 5C. The older women’s last would need to have a slightly narrower back because women’s feet become bonier in the heel as they go into their senior years and a last for the younger women would need to have a rounder cross section.

Shoe Lasts Then VS Now

Not too long ago manufacturers all owned their own lasts and guarded these designs closely. Now fewer manufacturers employ a last maker as most footwear is made in mass production when they will suggest and lend a last. The last information is vitally important to a shoe fitter and retailer.

For customers looking for shoes made with a similar fit to a pair you may have previously had, it’s best to visit your nearest Begg Shoes Shop. One of our professionally qualified shoe fitters will help you to find shoes made on the same last in the next seasons range, so that you can buy a shoe that is made on a last that is comfortable and fits you properly.

In the ideal world we would all have our own last and have bespoke shoes made for us. Sadly this is not economic, but at least you have us at Begg Shoes to try to help you.